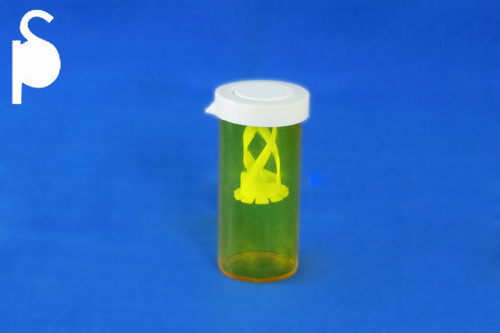

Dusting Powder Containers

Dusting Powder Containers Specification

- Leak Protection

- Leak-proof design

- UV Resistant

- Yes

- Color Pattern

- Plain or Customized

- Plastic Type

- Polypropylene (PP)

- Surface Finish

- Smooth

- Density

- Gram per cubic centimeter(g/cm3)

- Tensile Strength

- High tensile strength

- Melting Point

- 130C - 170C

- Heat Resistance

- Yes

- Type

- Talcum Powder Containers ( Squre & Round type)

- Material

- High-quality Plastic

- Shaping Mode

- Injection Molding

- Length

- Customizable

- Weight

- Lightweight (As per Client Requirements)

- Hardness

- Durable

- Plastic Molding Type

- Injection Molded

- Color

- As per Client Requirements

- Size

- Available in multiple sizes

About Dusting Powder Containers

Dusting powder containers are a type of container designed for storing and dispensing dusting powder. Dusting powder is a fine, powdery substance used to absorb moisture and reduce friction on the skin. It is commonly used in cosmetics, personal hygiene, and medical applications.Dusting powder containers come in a variety of shapes and sizes, from small, travel-sized containers to larger containers for home use. They are typically made from plastic, metal, or glass, and may feature a variety of dispensing mechanisms, such as a shaker top or a puff applicator.

Some dusting powder containers are designed for specific applications, such as foot powder containers, which are often larger and may feature a longer spout for easy application to the feet. Other dusting powder containers may be designed for use with specific powders, such as talc or cornstarch.

Dusting powder containers are often used in conjunction with other personal hygiene products, such as body powder, foot powder, and dry shampoo. They can be a convenient and practical way to apply these products while reducing mess and waste.

Versatile Shapes and Capacities

Customers can choose from square or round talcum powder containers to best suit their branding and handling preferences. Offered in 50g, 100g, 150g, and 250g standard sizes, capacities are also customizable to meet specific requirements. This adaptability supports a wide range of applications for personal care brands and manufacturers.

Durable and Safe Materials

Manufactured from high-quality, food-grade polypropylene (PP), these containers meet stringent safety standards for product quality and consumer health. The injection molding process ensures uniformity, excellent tensile strength, heat resistance, and UV protection, making them suitable for various environments and export needs.

Customizable Branding and Presentation

Personalize your containers with a choice of plain or customized color patterns, screen printed graphics, or labeling. Multiple color and finish options allow your packaging to communicate brand identity effectively. The smooth surface and secure cap designs combine aesthetics with practical performance.

FAQs of Dusting Powder Containers:

Q: How can I select the right size and shape for my dusting powder container?

A: You can choose from available capacities50g, 100g, 150g, 250gor specify a custom size to match your product needs. Both square and round shapes are offered, providing flexibility for branding and convenience.Q: What closure mechanisms do these containers offer and how do they prevent spillage?

A: The containers are equipped with either a secure screw cap or a flip top closure, both precisely engineered to ensure a tight fit and prevent leakage or accidental spillage during storage and transport.Q: Can these talcum powder containers be customized in terms of color and design?

A: Yes, the containers are available in client-specified colors and feature options for either plain or custom patterns. Branding can be further enhanced through screen printing or labeling according to your requirements.Q: What material are these containers made from, and are they recyclable?

A: Each container is manufactured using high-quality, food-grade polypropylene (PP) through an injection molding process. They are 100%% recyclable, supporting environmentally-conscious initiatives.Q: Are these containers suitable for food-grade products and do they maintain freshness?

A: Absolutely. The containers comply with all relevant food safety standards and are designed to resist odors, preserving the freshness and quality of your product over time.Q: Where are these containers manufactured and can they be supplied in bulk?

A: We are exporters, manufacturers, suppliers, and traders based in India, capable of fulfilling both small and bulk orders according to your specifications. Minimum order quantity (MOQ) is determined as per order details.Q: What additional benefits do these dusting powder containers offer for packaging needs?

A: Beyond strong leak protection and odor resistance, the containers are lightweight, UV and heat resistant, and have a smooth finish, ensuring safety and convenience for both manufacturers and end-users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Containers and Bottles Category

Seal Type Containers

Minimum Order Quantity : 10000 Pieces

Color : As per Client Requirements

Type : Liquid Containers

Size : Multiple Sizes Available

Length : Customizable

Shaping Mode : Injection Molding

Dexa Containers

Minimum Order Quantity : 10000 Pieces

Color : As per Client Requirements

Type : Dexamethasone Tablet Containers

Size : Standard

Length : 85 mm

Shaping Mode : Injection Mould

Secure Pack Containers

Minimum Order Quantity : 10000 Pieces

Color : As per Client Requirements

Type : Powder Containers

Size : Various sizes available

Length : Standard

Shaping Mode : Injection Molding

Barni or Ogle Jars

Minimum Order Quantity : 10000 Pieces

Color : As per Client Requirements

Type : Powder Containers

Size : 100gm to 1kg

Length : Standard (varies as per size selection)

Shaping Mode : Injection Molded

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese