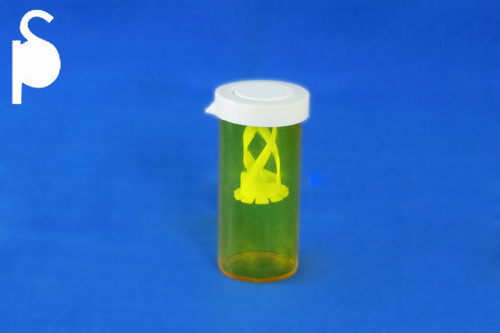

Ribbed Jars

Ribbed Jars Specification

- UV Resistant

- Not Specified

- Color Pattern

- Ribbed

- Melting Point

- Not Specified

- Leak Protection

- Yes

- Plastic Type

- Not Specified

- Density

- Gram per cubic centimeter(g/cm3)

- Surface Finish

- Glossy

- Tensile Strength

- Not Specified

- Heat Resistance

- Yes

- Type

- Powder Containers

- Material

- Plastic

- Shaping Mode

- Injection Moulding

- Length

- Not Specified

- Weight

- Not Specified

- Hardness

- Rigid

- Plastic Molding Type

- Injection Moulding

- Color

- As per Client Requirements

- Size

- From 110ml to 1800ml

- Cap Type

- Screw or Flip Top

- Chemical Resistance

- High

- Shape

- Cylindrical with Ribbed Pattern

- Odor Resistant

- Yes

- Food Grade

- Yes

- Transparency

- Semi-Transparent or Opaque

- Branding Options

- Screen Printing, Labeling

- Impact Resistance

- High

- Usage Temperature

- Up to 70°C

- Recyclable

- Yes

- Stackable

- Yes

- Application

- Cosmetic, Pharmaceutical, Food Storage

- Customer MOQ

- Negotiable

- Customization

- Available

- Neck Diameter

- Variable as per Size

- Sealing Type

- Air Tight

About Ribbed Jars

Versatile Applications

These ribbed jars are engineered to meet the diverse needs of cosmetics, pharmaceuticals, and food storage. With their food-grade certification, airtight seals, and high chemical resistance, they ensure safe packaging for powders, creams, and edible products. The variable neck diameters and customizable sizes enable packaging flexibility to suit both individual and commercial requirements.

Customizable Design & Branding

Choose from semi-transparent or opaque finishes, with ribbed cylindrical shapes in sizes from 110ml to 1800ml. The jars are available in custom colors and support multiple branding options such as screen printing and labeling, ensuring your product stands out on the shelf. The glossy surface and stackable feature make both storage and display efficient and appealing.

Quality Manufacturing from India

Produced via advanced injection moulding techniques, these jars are crafted for rigidity and impact resistance, making them ideal for shipping and handling. As a leading exporter, manufacturer, and supplier in India, we ensure high standards of quality, leak protection, and regulatory compliance in every batch.

FAQs of Ribbed Jars:

Q: How do the ribbed jars ensure product safety during storage and transport?

A: Ribbed jars are designed with airtight screw or flip-top caps, high impact resistance, and leak protection features, safeguarding contents against contamination, spillage, and external factors during storage and shipping.Q: What customization options are available for size, color, and branding on these jars?

A: Clients can choose jar sizes between 110ml and 1800ml, select from semi-transparent or opaque finishes, specify custom colors, and opt for branding through screen printing or labeling to match their branding requirements.Q: When should I use ribbed jars with high chemical and odor resistance?

A: These jars are ideal for storing sensitive powders, creams, or edible products that may require protection from chemical exposure or odor retention, commonly in pharmaceutical, cosmetic, or food industry settings.Q: Where are these ribbed jars manufactured and exported from?

A: All ribbed jars are produced in India by experienced manufacturers using precise injection moulding, making them suitable for domestic and international markets.Q: What is the process for ordering customized ribbed jars in bulk?

A: After choosing size, color, and branding options, you can negotiate the minimum order quantity (MOQ) with our team. Production commences post-finalization of specifications, ensuring timely fulfillment of your bulk customization needs.Q: How can these jars be utilized in the food industry safely?

A: The jars are food grade, heat resistant up to 70C, and offer airtight, odor-resistant storage. They maintain content integrity for spices, powders, and edibles while being recyclable and stackable for efficient handling.Q: What are the key benefits of using ribbed jars made via injection moulding?

A: Injection moulding ensures consistent quality, rigid structure, precise shaping, and high impact resistance, resulting in durable containers that meet stringent safety and performance standards across industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Containers and Bottles Category

Dexa Containers

Minimum Order Quantity : 10000 Pieces

Size : Standard

Color : As per Client Requirements

Type : Dexamethasone Tablet Containers

Tensile Strength : 23 MPa

Length : 85 mm

Seal Type Containers

Minimum Order Quantity : 10000 Pieces

Size : Multiple Sizes Available

Color : As per Client Requirements

Type : Liquid Containers

Tensile Strength : 21 MPa

Length : Customizable

Secure Pack Containers

Minimum Order Quantity : 10000 Pieces

Size : Various sizes available

Color : As per Client Requirements

Type : Powder Containers

Tensile Strength : High

Length : Standard

Shampoo Bottles

Minimum Order Quantity : 10000 Pieces

Size : 100ml, 200ml, 250ml, 500ml (Other sizes available as per requirements)

Color : As per Client Requirements

Type : Shampoo Bottles

Tensile Strength : 2040 MPa (Based on plastic type)

Length : 615 cm (Varies by capacity)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese